Periodic Testing of Gas Cylinders

Periodic testing of gas cylinder to TPED, UKAS and DOT accredited standards.

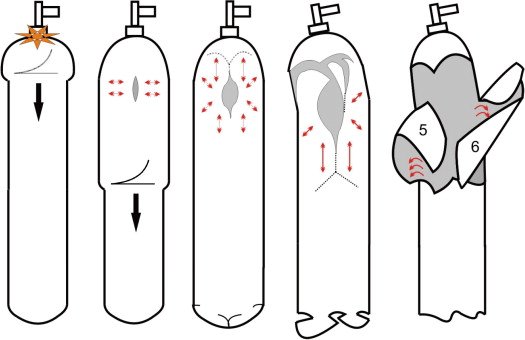

All compressed gas cylinders have to be hydrostatically tested every 10 years to ensure they are safe and fit for purpose. Marine Retrofit has in-house test facilities to enable us to carry out cylinder testing. We hydrostatically test and maintain fire suppression cylinders, liferaft cylinders and BA cylinders to both TPED, UKAS and American DOT standards.Hydrostatic testing involves the cylinder being filled with water and placed inside a water-filled high-pressure chamber. Water pressure inside the cylinder is increased (150% of maximum working pressure) causing the cylinder to expand slightly.

This in turn displaces a small amount of water from within the chamber, which is collected and measured. If the cylinder expansion is within regulation limits (< 5%), then the cylinder has passed and can be certified fit for purpose. Compliant cylinders are dried out, stamped as tested with the current month and year, refilled with the appropriate suppression agent and placed back in service. Failed cylinders must be destroyed.

Our in-house inspection body is accredited by TPED, UKAS and DOT and ensures that all cylinders are tested impartially and to the highest possible standards. Our fully trained inspectors conduct periodic testing of fire suppression cylinders for Facilities Management and Fires suppression engineers all over the world. Our state-of-the-art equipment is routinely calibrated and verified by independent inspection bodies to ensure our own in-house testing is accurate and effective.

Hydrostatic Testing & Tank Inspection

Hydrostatic testing is the most widespread way to inspect a compressed gas container for leaks or defects. The cylinder undergoes hydrostatic testing with the purpose of checking whether it can safely hold its rated pressure. Hydrostatic testing is critical when it comes to compressed gas containers because they can explode in case if they fail when containing compressed gas.

A hydrostatic test includes filling the container with a practically incompressible liquid (water) and examining it for leaks or changes in shape. The test pressure is considerably higher than the operating pressure to ensure safety. Usually 150% of the operating pressure is applied. Water is used in hydrostatic testing as it is almost incompressible and will only expand by a very small amount.

Hydrostatic Testing & Tank Inspection

In case of high-pressure gas use, it could exceed its compressed volume, posing a great risk of explosion. All compressed gas containers need regular hydrostatic testing. The frequency of the maintenance depends on the cylinder material.

The DOT recommends visual inspections to be performed on a regular basis as well. The DOT demands that hydrostatic retesting and re-qualification would be handled by registered specialists who have been certified. Marine Retrofit all the necessary qualifications for hydrostatic testing are met, so you can trust our company for examining your compressed gas cylinders.

The object of the pressure tank testing is to check if there is a significant drop of pressure which usually signals of a crack or hole in the tank. Pressure accumulation is a potentially dangerous situation, that’s why this kind of testingshould be conducted by a plumbing professional.

Marine Retrofit is a specialist in hydrostatic testing and cylinder maintenance. Our customers include the military, major gas manufacturers, independent welding supply companies, fire extinguisher companies, fire departments, and municipalities.

The Benefits of Hydrostatic Cylinder Services

Preventing dangerous accidents

Hydrostatic cylinder testing is designed to catch even small structural problems early, preventing catastrophic accidents and injuries.

Cost savings

Instead of replacing older cylinders before testing is due, you can have them recertified and save money.

Meeting TPED / DOT specifications

Instead of replacing older cylinders before testing is due, you can have them recertified and save money.

Avoiding penalties and fines

Transporting cylinders that are outdated or have not been tested can lead to costly fines and other penalties, jeopardizing your business.

providing peace of mind

When you have cylinders that contain flammable or dangerous materials, regular hydrostatic cylinder testing ensures that they are safe and leak-free.

Increase efficiency

By working with a single partner to achieve a seamless solution throughout your project lifecycle.

FIRE-FIGHTING PRODUCTS AND SOLUTIONS

Fire protection systems

We offer a range of fire suppression solutions, including natural and chemical agents, plus gas/water-combined and water mist systems for diverse industries

Fire extinguishers

We offer a wide selection of high-quality fire extinguishers with various approvals, including CE Mark and others, ensuring compliance and reliability.

Fire systems maintenance

Fire protection systems need regular servicing to maintain optimal performance and ensure effective fire combat in case of emergencies.

Halon Fire Extinguishers

Halon fire extinguishers use halon gas to interrupt combustion. Though effective, they are phased out due to environmental concerns, replaced by alternatives.

Marineretrofit offers top-notch maritime solutions, combining extensive talent and expertise. Whether you need portable fire equipment, fire protection systems, installation, repair, or ship overhaul, we’re here to provide comprehensive safety and support tailored to your needs. Trust Marineretrofit for all your maritime safety solutions.